CONSULTING

TESTING

DEVELOPMENT

RESEARCH

Outgassing

Outgassing of materials in thermal vacuum

To qualify materials for their suitability for space applications, assessment of outgassing properties is required. “Outgassing” is defined as the mass loss of a sample due to thermal vacuum conditioning. AAC offers outgassing tests in accordance to the ESA standards ECSS-Q-ST-70-02C (“Thermal vacuum outgassing test for the screening of space materials”), ASTM E595 (“Standard Test Method for Total Mass Loss and Collected Volatile Condensable Materials from Outgassing in a Vacuum Environment”) and ECSS-Q-TM-70-52A (“kinetic outgassing of materials for space”).

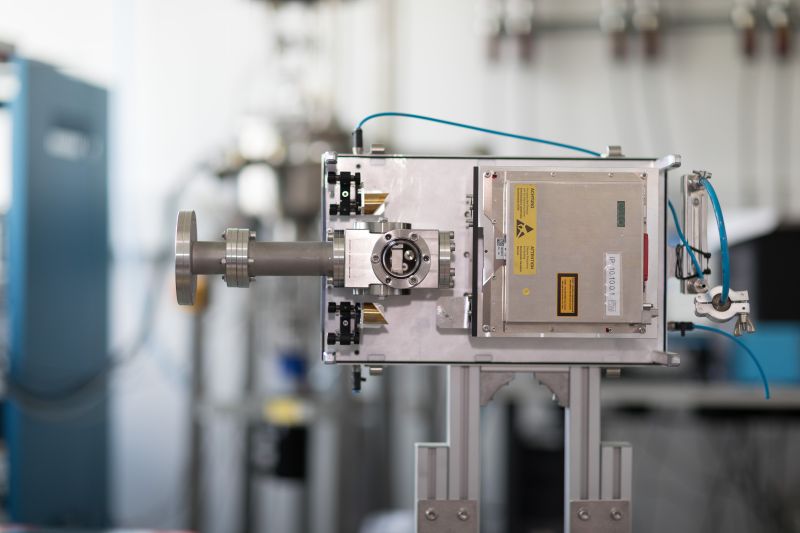

AAC offers a facility for analysing mass transport of materials in vacuum. The facility measures in-situ mass loss through thermal vacuum (evaporation), residual gas analysis (RGA), and mass gain via Thermal Quartz Crystal Microbalance (TQCM), including Infrared-Reflection-Absorption-Spectroscopy (IRRAS) to determine functional groups of collected materials.