CONSULTING

TESTING

DEVELOPMENT

RESEARCH

Material & Failure Analysis

Engineering office for failure analysis & material development

AAC is an established engineering office specializing in the investigation of surfaces, coatings, and materials, as well as material development projects.

With state-of-the-art equipment, AAC conducts investigations as a service for industrial companies, including surface characterizations, tribological studies, mechanical testing, and failure analysis. These services are crucial in understanding the performance, durability, and integrity of materials in various applications, ensuring that industrial components meet stringent quality and safety standards.

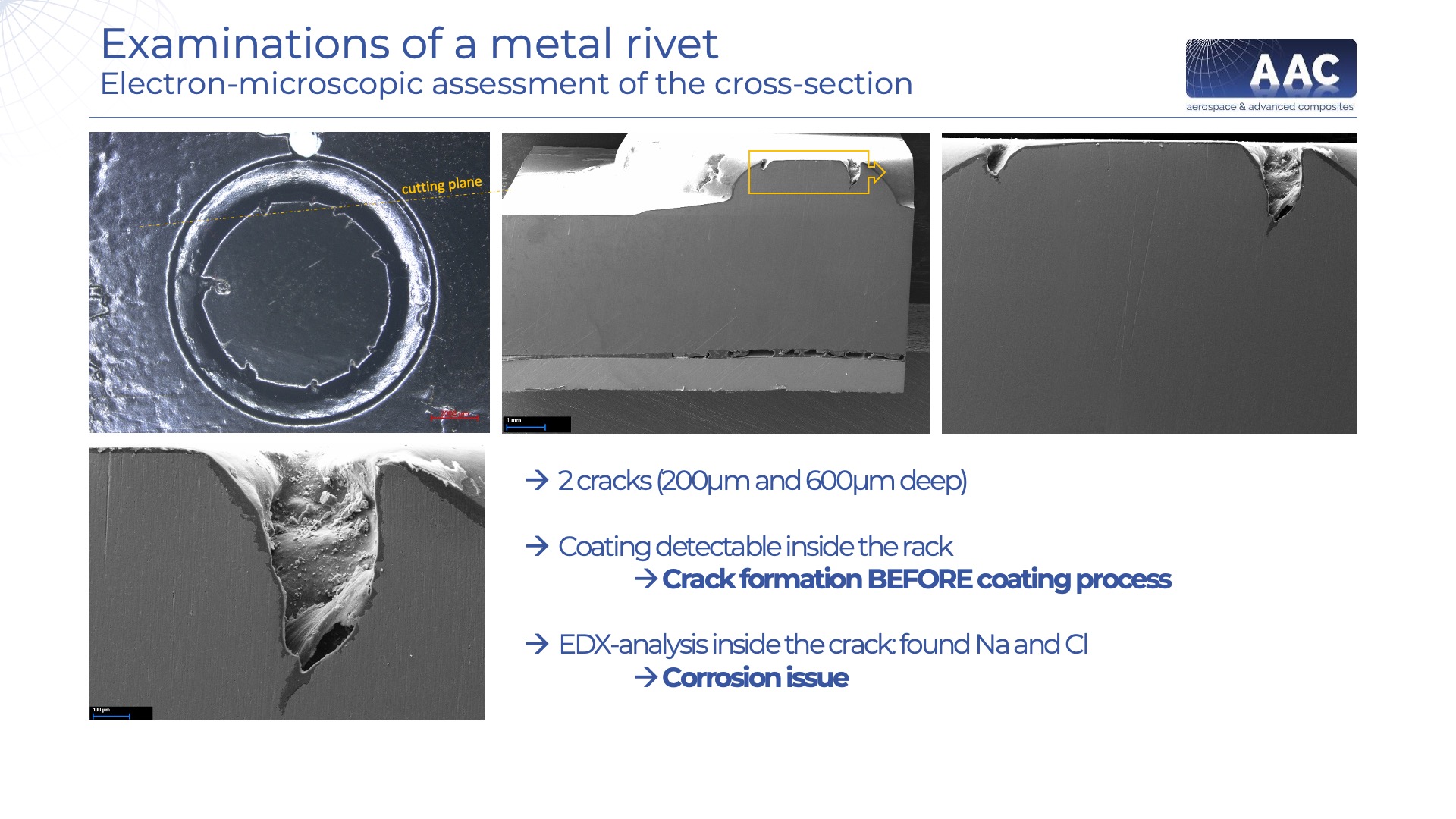

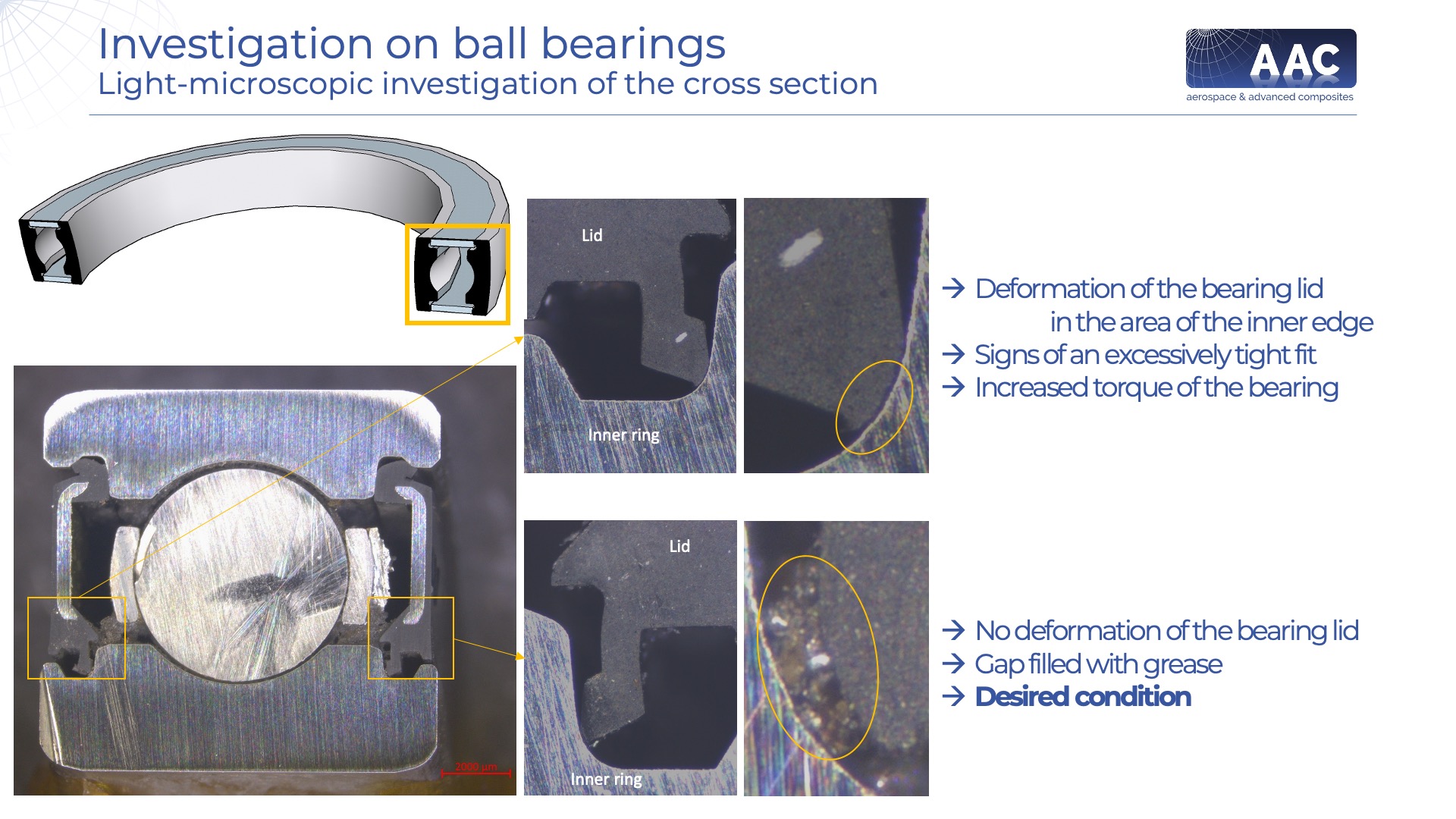

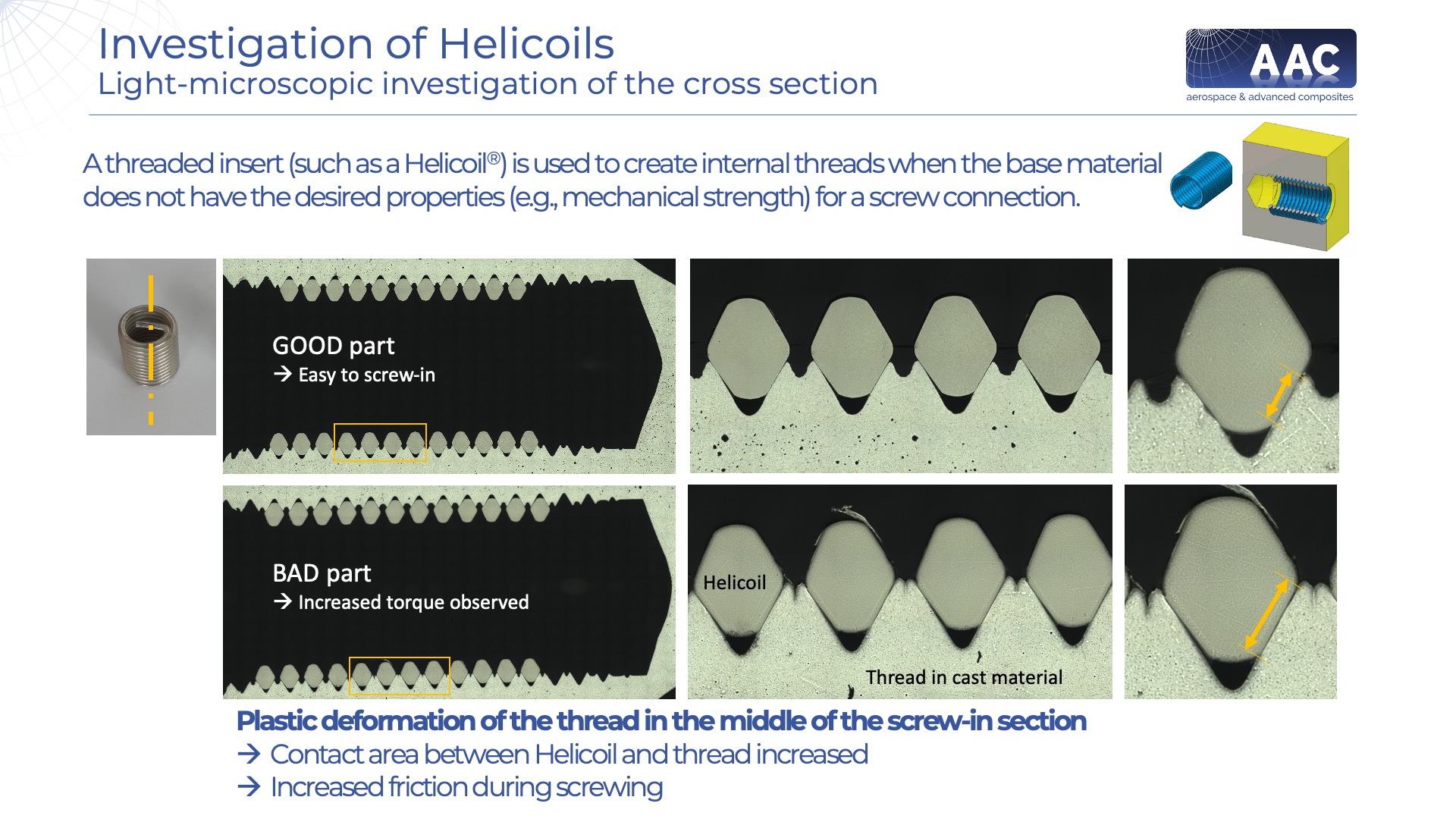

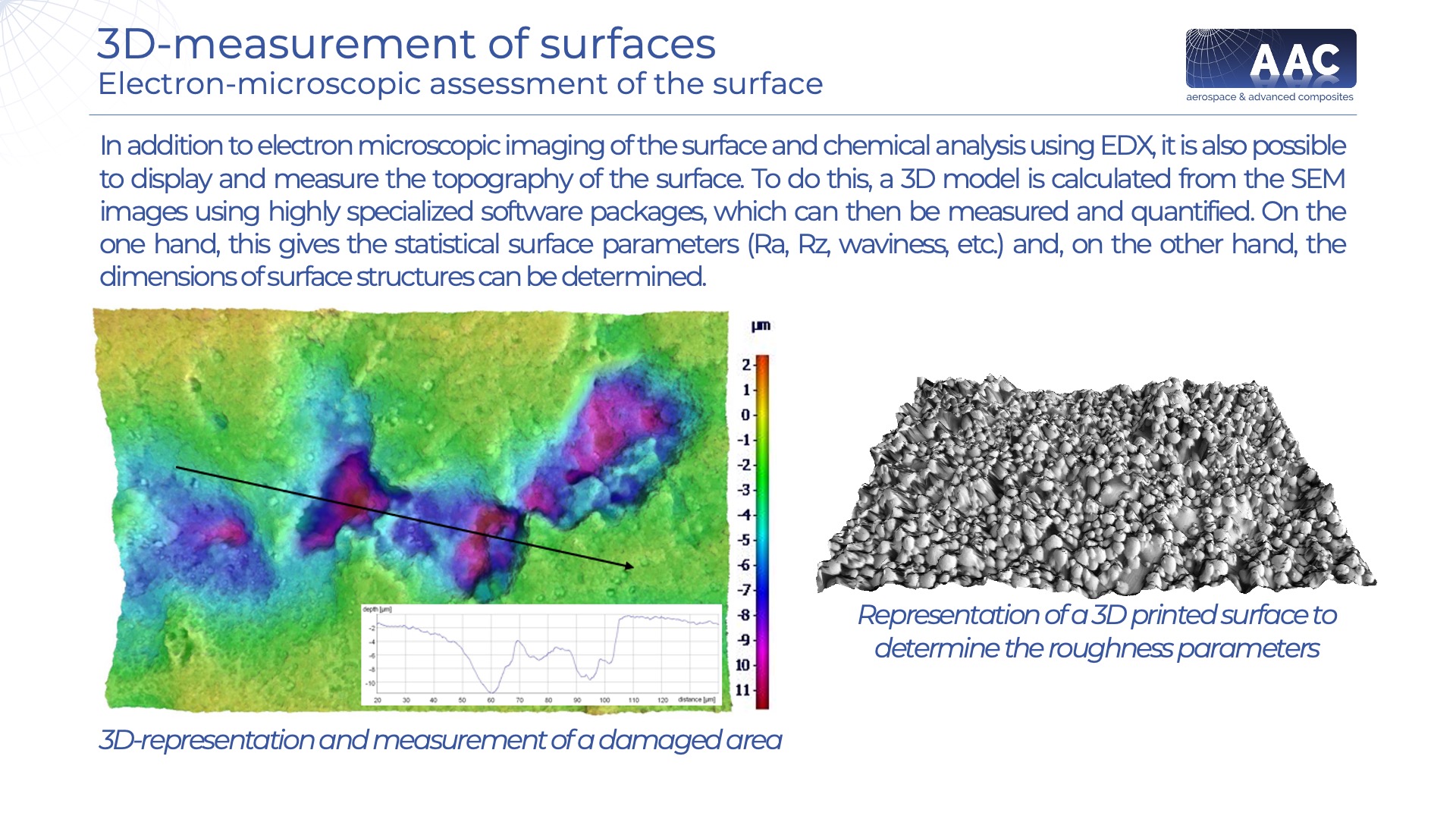

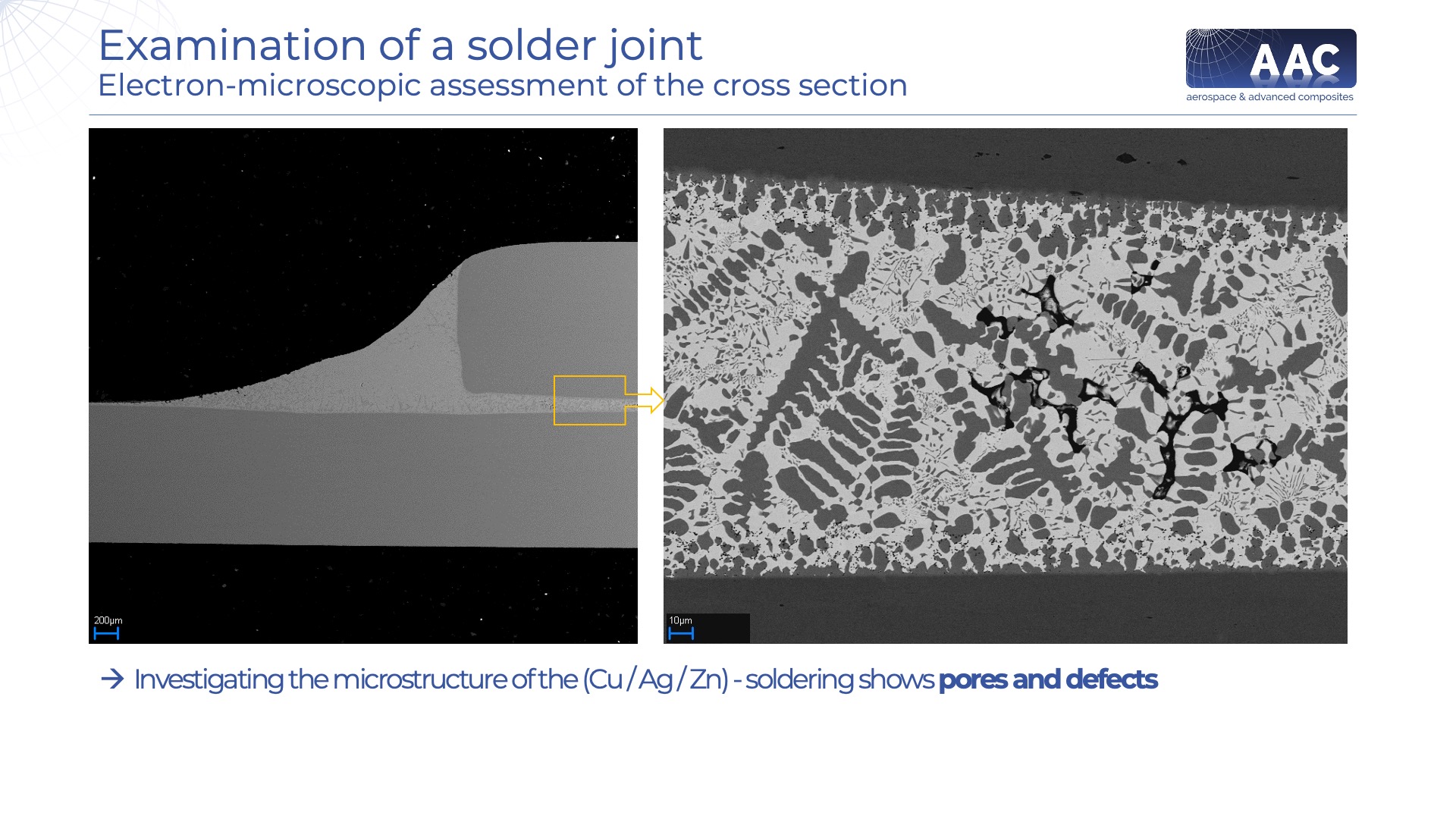

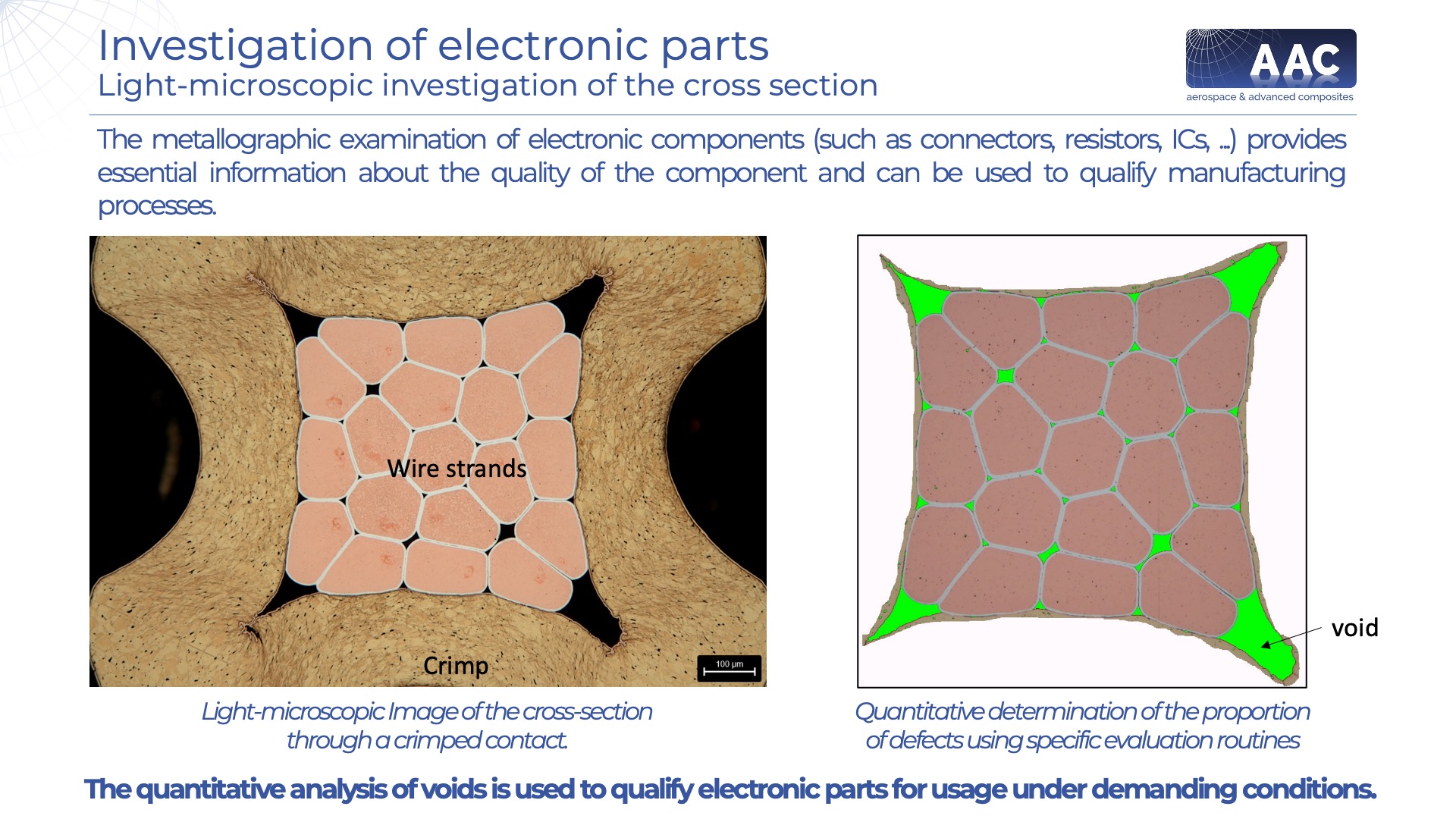

Material analysis at AAC involves a comprehensive suite of techniques designed to evaluate the chemical composition, microstructure, mechanical properties, and performance characteristics of materials. This includes techniques such as scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), X-ray diffraction (XRD), and various forms of spectroscopy and thermal analysis. These methods allow AAC to provide detailed insights into material properties, guiding the optimization and development of new materials.

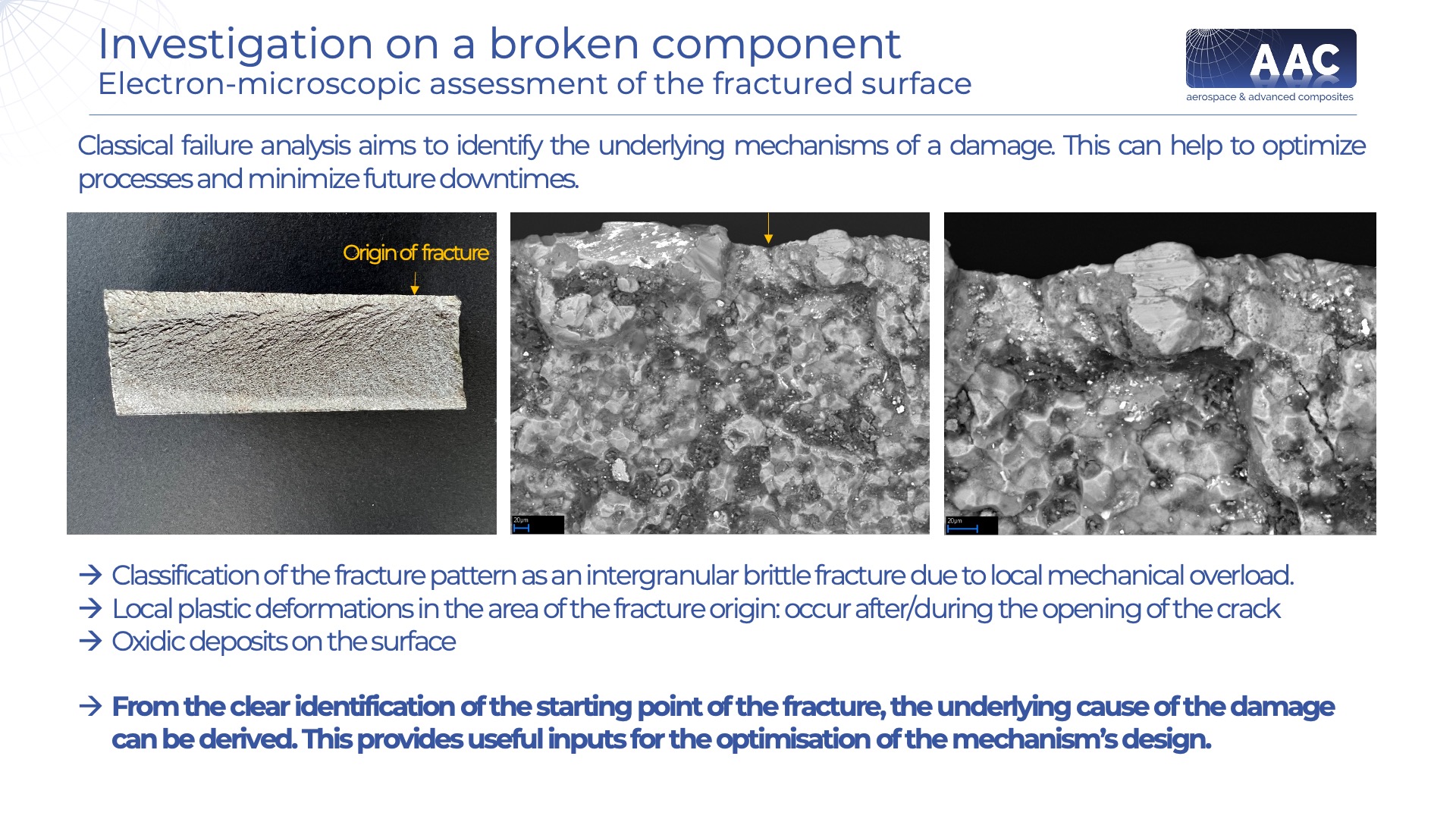

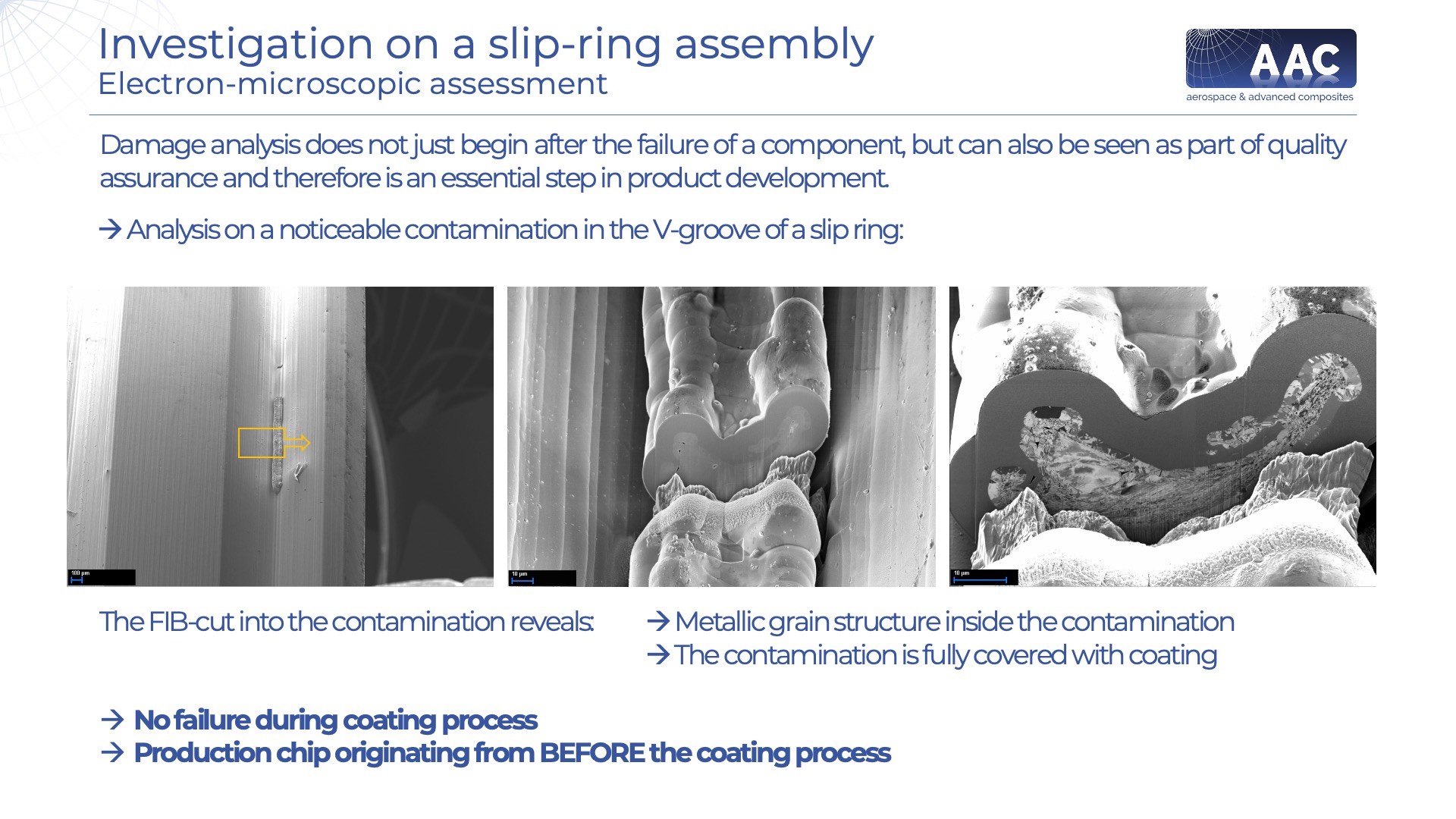

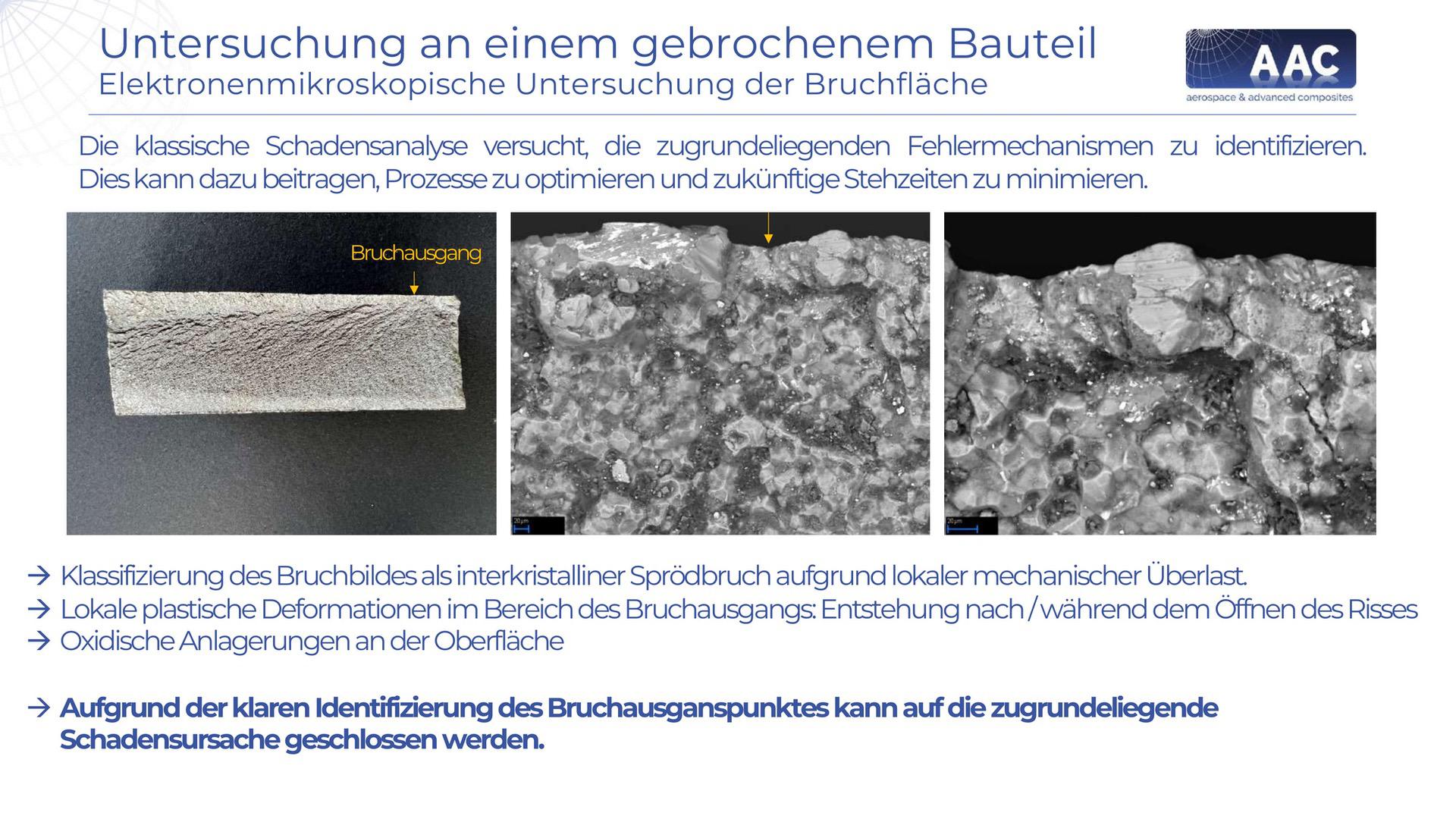

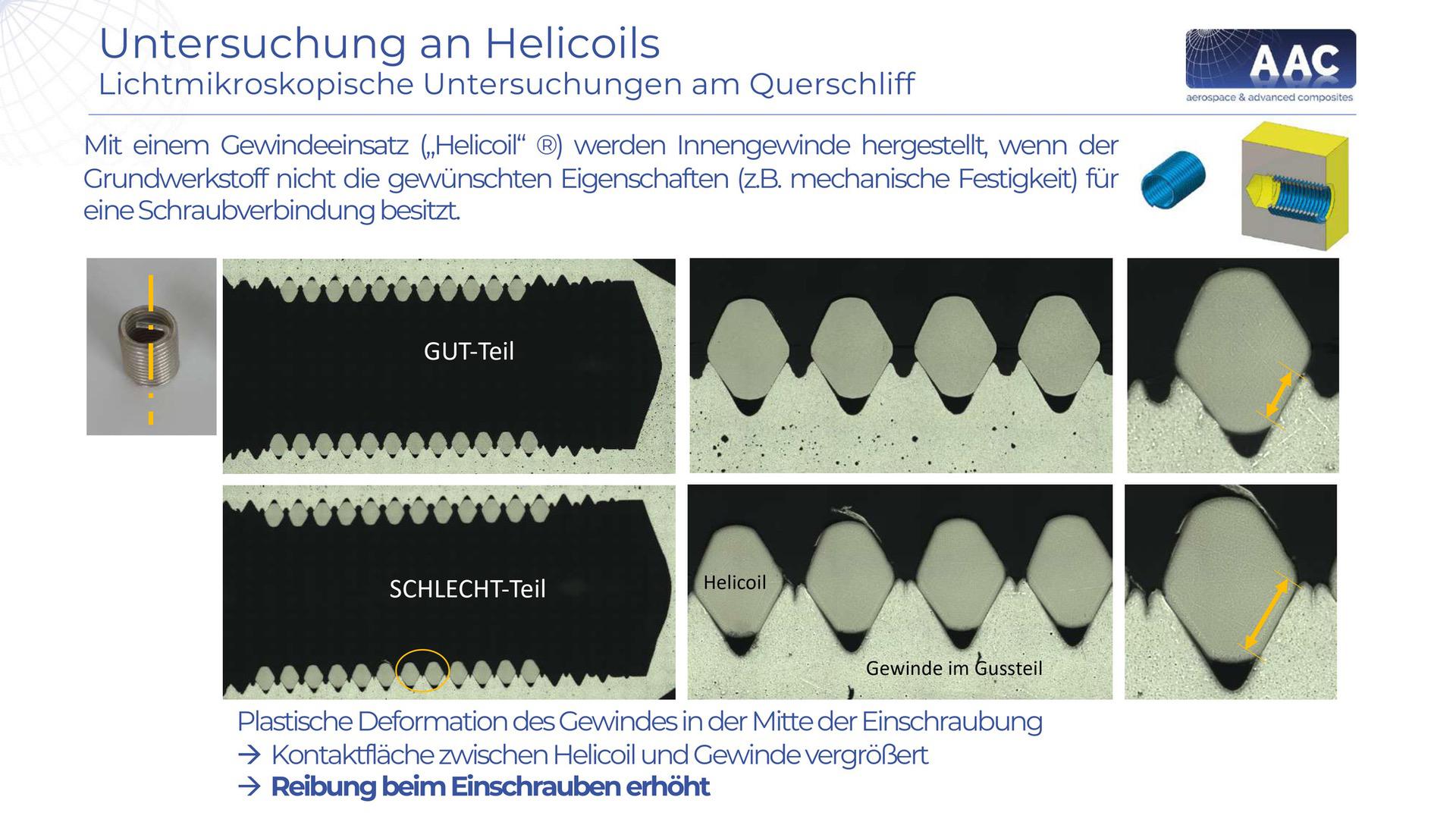

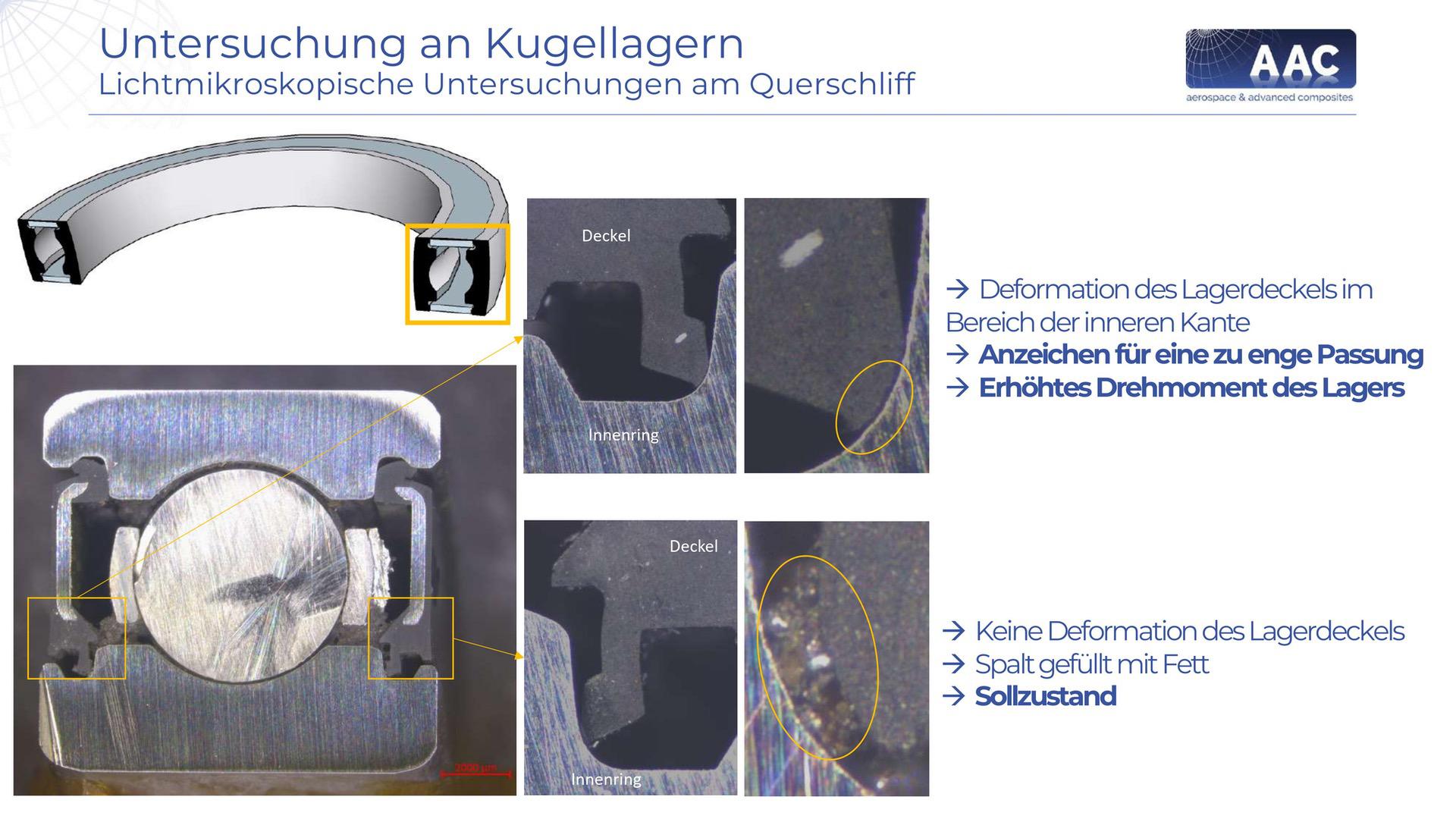

Failure analysis is another critical service offered by AAC, aimed at identifying the root causes of material and component failures. This process involves a systematic investigation that combines visual inspection, non-destructive testing, fractography, metallography, and mechanical testing. By understanding the failure mechanisms, AAC helps clients implement corrective actions to prevent future failures, improve product designs, and enhance overall reliability. The failure analysis process not only identifies immediate issues but also contributes to long-term improvements in material performance and safety.

AAC supports clients in the planning and implementation of their projects through its expertise in material development, material and failure analysis, as well as the use of simulation tools and microstructural analyses. AAC has specialized facilities for testing materials, coatings, and components in industrially relevant environments. These capabilities enable AAC to simulate real-world conditions and assess how materials and components will perform under various stresses and environmental factors. Together with partners from industry and research, AAC develops new materials and components in nationally, European, and ESA-funded projects. This collaborative approach ensures that AAC remains at the forefront of technological advancements, continually integrating the latest scientific discoveries into their material analysis and development processes. The collaborative projects also foster innovation, driving the creation of materials that meet the evolving demands of various industries, including aerospace, automotive, energy, and more. In nationally and European-funded research projects, new testing methods or facilities, as well as new materials and components, are developed to expand knowledge and competence in existing and new segments. AAC’s role in these projects often involves pioneering new material analysis techniques and developing cutting-edge testing protocols that push the boundaries of current technology. These advancements not only benefit AAC’s clients but also contribute to the broader scientific and engineering communities. AAC’s dedication to material analysis and failure analysis positions it as a leader in the field, providing invaluable services that underpin the safety, reliability, and innovation of industrial components and materials. By continually refining their analytical techniques and expanding their testing capabilities, AAC ensures that they can meet the ever-increasing demands of modern engineering challenges, helping their clients achieve success in their respective industries.

Examples of Our Failure Analyses in Images

Download all examples of our failure analyses as PDF.Download all examples of our failure analyses as PDF.

Products and Services

As an engineering office, AAC offers services in the fields of material and surface analysis, testing, and characterization. Our services encompass numerous procedures such as:

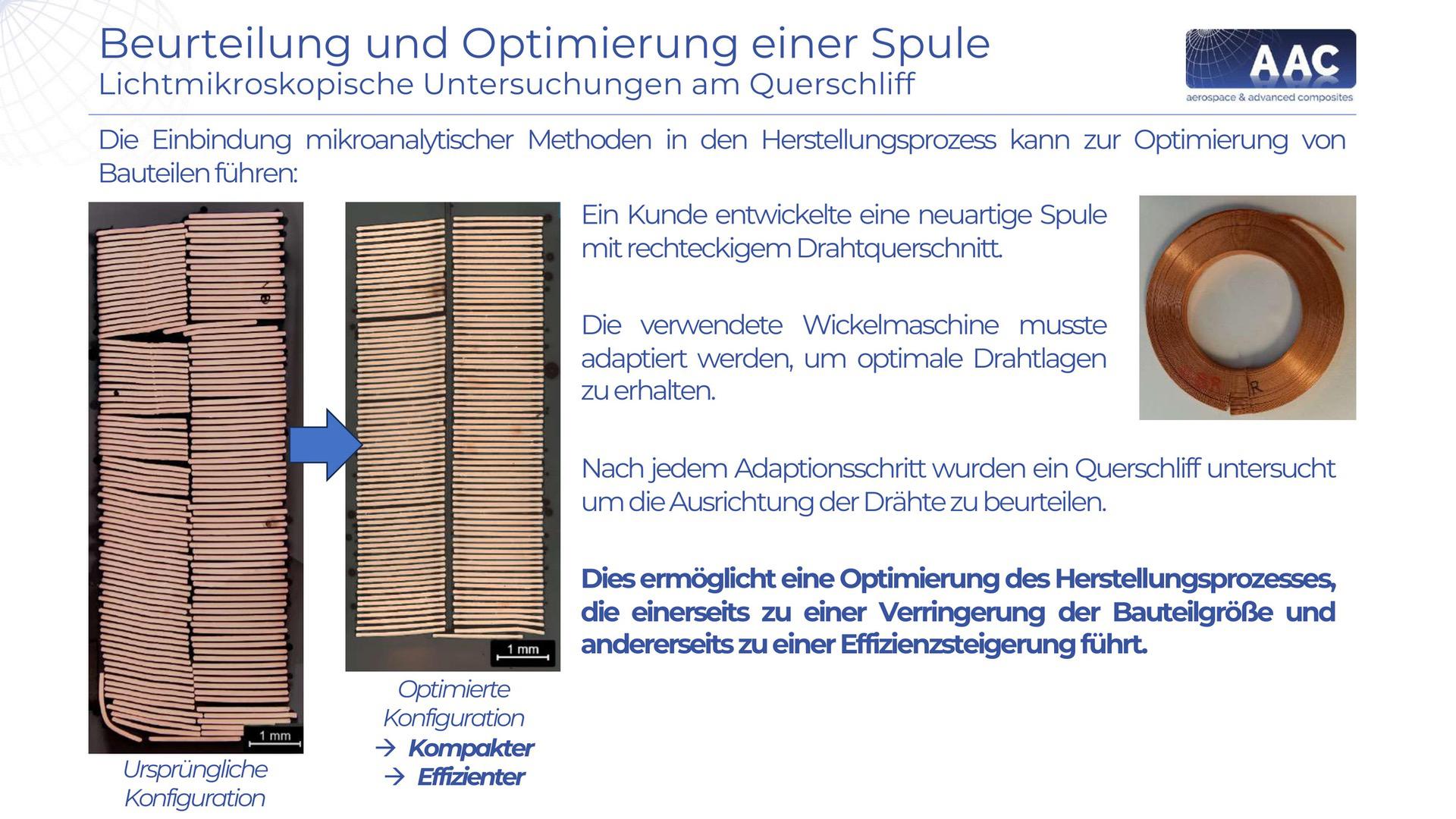

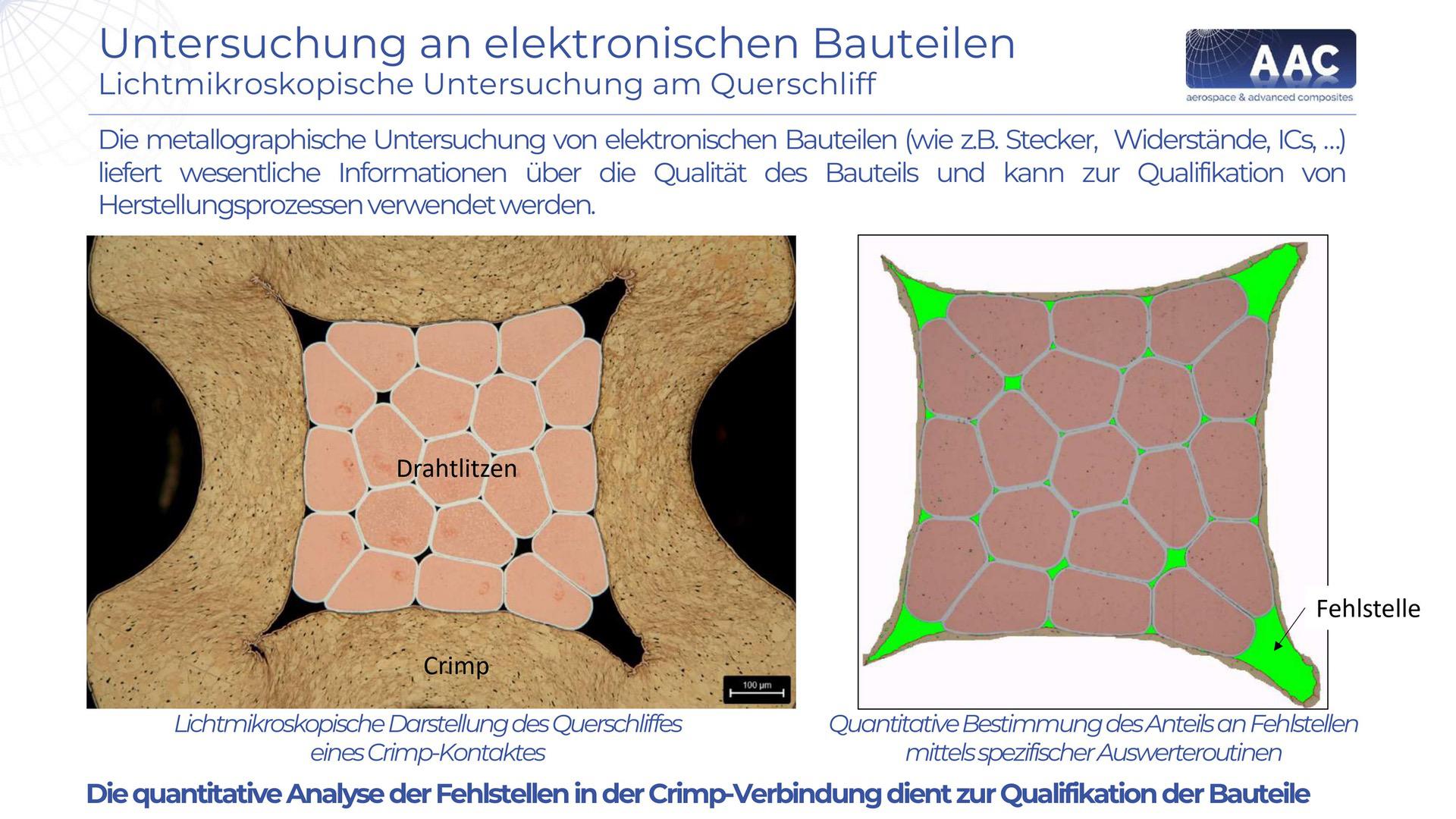

- Metallography

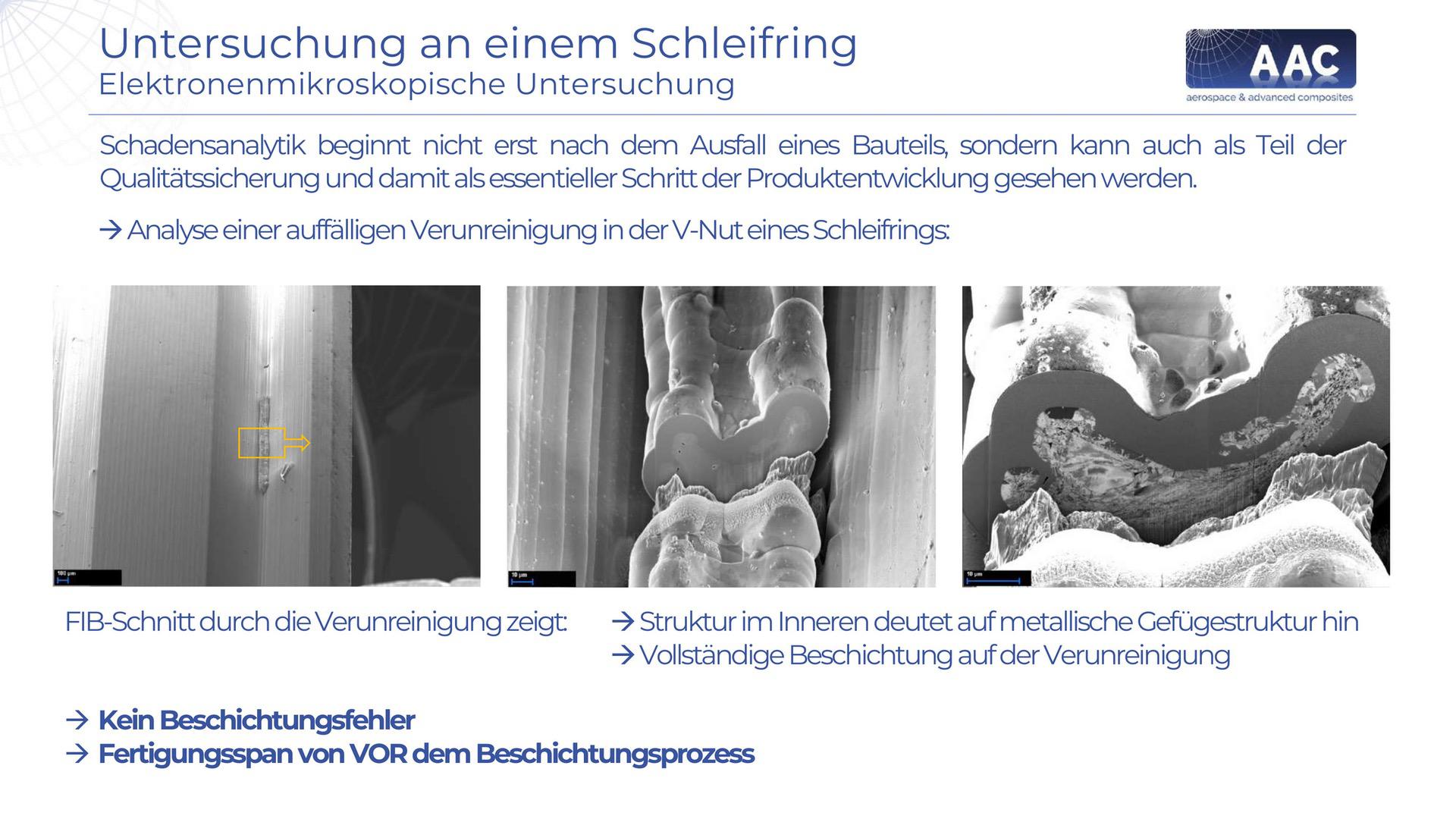

- Failure analysis

- Scanning electron microscopy (SEM)

- Surface characterization

- Friction coefficient measurement

- Adhesion testing

- Hardness testing

- Coating thickness measurement

- Nanoindentation

- Mechanical testing

- Chemical analysis

- Density determination

- Thermal analysis

- Dynamic light scattering (DLS)

- Coating characterization

- Weathering tests

- And much more

AAC also offers research and development services for customer-oriented solutions, particularly for additive manufacturing technologies, functional coatings, and composite materials.

In addition, AAC provides specialized coating products with easy-to-clean and non-stick properties (AAC 2000 EC, AAC 3001 AN) for specific industrial applications.

FAQ – Failure Analysis and Material Development

Failure analysis is the process of investigating and identifying the causes of a material or component failure. This analysis is important to understand the exact reasons for the failure, prevent future issues, extend the lifespan of products, and minimize safety risks.

AAC employs a variety of methods in failure analysis, including visual inspection, scanning electron microscopy (SEM), metallographic examinations, mechanical testing, and chemical analysis. These methods help in thoroughly examining the structure and composition of the damaged material.

Through failure analysis, AAC can identify the exact causes of material failures. These insights enable manufacturers to optimize design and manufacturing processes, select materials that better meet requirements, and implement preventive measures to enhance the reliability and quality of their products.

Material development refers to the process of researching, designing, and optimizing new materials with improved properties. This can include the development of materials that are lighter, stronger, more heat-resistant, or more environmentally friendly.

AAC offers comprehensive services in material development, including the research and development of new materials, characterization and testing of material properties, and support in industrial application implementation. AAC works closely with clients to develop customized solutions for specific requirements.

AAC supports material development in the industry by providing expertise in material characterization, conducting mechanical and thermal tests, and utilizing advanced simulation tools. These services help evaluate and improve the performance and reliability of new materials.

Yes, AAC can assist in the material development of sustainable materials. AAC works on the development and testing of materials that are more environmentally friendly, have longer lifespans, and are recyclable. By combining research and advanced analytical techniques, AAC contributes to the development of sustainable material solutions that reduce the environmental footprint.