CONSULTING

TESTING

DEVELOPMENT

RESEARCH

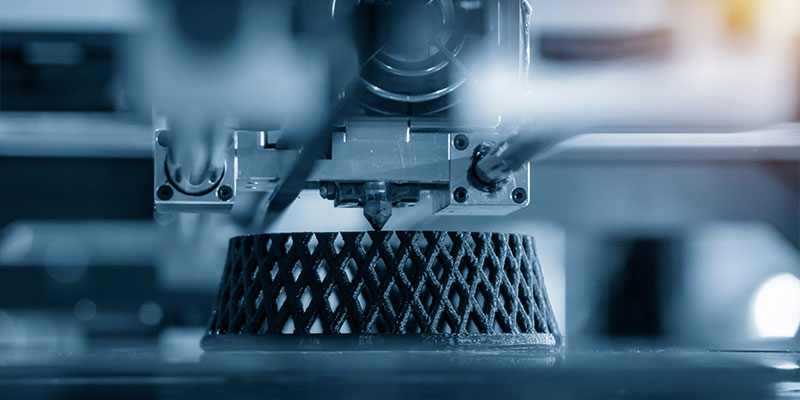

3D-Printing

Characterization & Testing of 3D- and 4D-printed materials

Additive Manufacturing Technologies offer new capabilities on design for complex parts. However, based on our expertise we know that there are still several drawbacks on the materials & processing side to overcome. Material properties depend strongly on the Additive Manufacturing Process and processing & post-processing parameter. Therefore, materials & components are usually not similar to their conventional produced counterparts (e.g. microstructure, surface roughness, mechanical properties, etc.)

AAC uses its special know-how developed during the last 10 years on materials microstructure and testing of materials and components even in extreme environments to improve the additive manufacturing processes of our partner lead to improved materials and components properties relevant for space applications. Thus development of new Additive Manufacturing processes, new alloys & composite material systems as well as new concepts in 4D-Printing to integrate additional functionalities to materials used in space are challenging and part of our daily business.