CONSULTING

TESTING

DEVELOPMENT

RESEARCH

Microstructural Analysis

Space materials, interpretation, correlation: microstructure – performance

Our experts act in the framework of national and international scientific and technological programs. We are familiar with many novel manufacturing technologies and investigation methods. The long-lasting expertise on a huge variety of materials – such as alloys, composites and coatings – allows us to work on the evolution of new material- and structural concepts for aerospace applications. The following methods are available:

- Materialography:

Unique preparation procedures (such as mechanical, electrochemical, chemical) allow us to provide in-depth analysis of materials and also enable high-quality failure and fracture analysis.

- (Micro)Hardness measurements:

Modern state-of-the-art equipment enables the (fully automated) investigation of hardness based on Vickers and Knoop with loads in the range of 0,25 g – 62,5 kg. Lateral resolutions in micro-meter range are feasible (e.g., line-scans, matrix-scans) to assess the lateral distribution of mechanical properties.

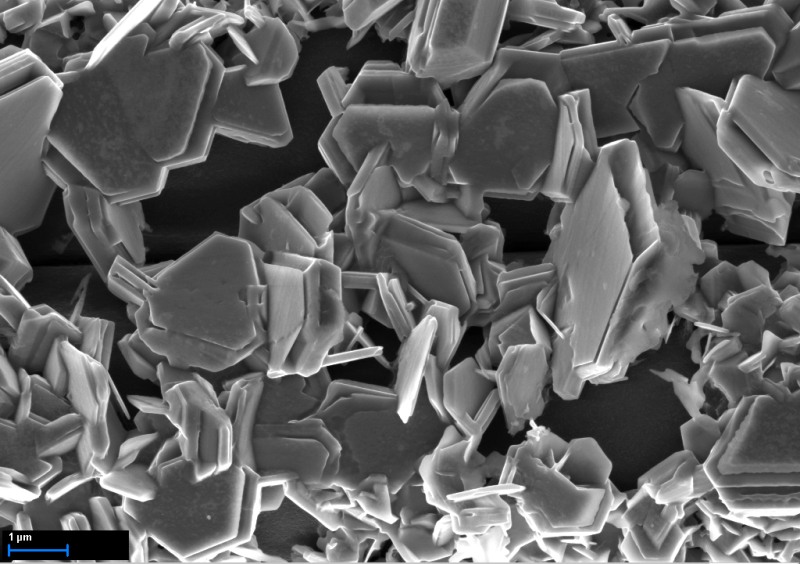

- Electron Microscopy:

Two high-resolution electron microscopes (SEMs) including advanced techniques such as Focused Ion Beam (FIB) and Electron Back-Scattered Diffraction (EBSD) are available to perform high-quality investigations. Energy Dispersive X-Ray Spectroscopy (EDS) allows to assess the chemical composition of materials in spots, lines or areas.

- Surface Analysis based on 3D-models:

The reconstruction of 3D-models and evaluation of the roughness parameters of surfaces recorded in high-resolution SEM is provided by using advanced evaluation software packages.