CONSULTING

TESTING

DEVELOPMENT

RESEARCH

Environmental Testing

AAC – Your Premier Partner for Environmental Testing

AAC specializes in top-notch testing services designed to assess the accelerated weathering and outdoor exposure of coatings and components. We’re your trusted partner in ensuring the durability and performance of your products in the harshest conditions.

Our weathering devices include:

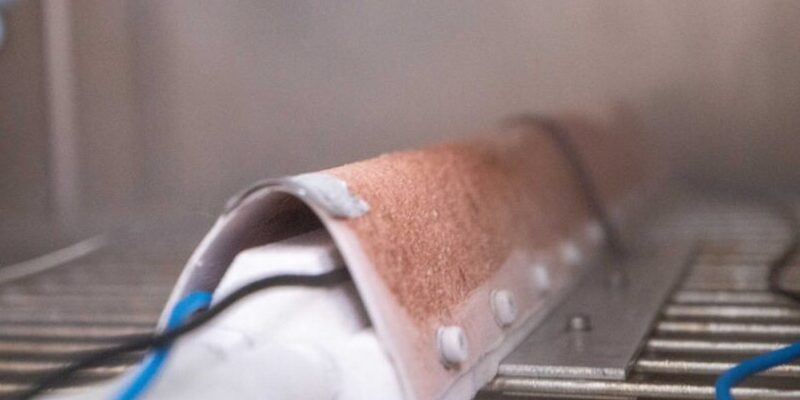

- Accelerated weathering tester: Our UV-Tester is equipped with a UVA-340 light source. The equipment simulates sunlight, rain, and dew, to assess your materials’ resistance to those conditions.

- Xenon test chamber: Our Xenon-Tester is fitted with a daylight F Filter. The device simulates the damage caused by full spectrum sunlight and rain (optional), enabling precise evaluation of your products.

- Pressure Cooker Test (Autoclave): A fast and reliable for screening the durability of your materials under extreme temperature and humidity conditions.

- Climate/ Thermal Chambers: Our chambers are optimized for a wide range of tests, including:

- Temperature Stability Testing: Assessing how products, components, devices, and materials, perform under constant temperatures.

- Thermal Cycling Tests: Capable of simulating extreme temperature fluctuations, even as low as -40°C, to gauge the impact on products, materials, components, and devices.

- Accelerated Aging Tests: Simulating conditions that accelerate the aging process to predict the long-term durability of products, materials and more.

- Humidity Stability Tests: Assess how your materials respond to various humidity levels, ensuring long-term reliability.

- Damp Heat Tests: Conforming to international standards such as IEC 61215, IEC 61646, and IEC 60068-2-30:2005.

At AAC, we offer a wide range of testing services tailored to meet both industry standards and/or your unique needs. Additionally, our capabilities extend beyond mere testing, as we complementary provide a comprehensive suite of surface and material characterization tests, all conducted in-house.

Our commitment to customer satisfaction goes beyond the norm. If you can’t find your specific testing requirement in the list above, don’t hesitate to get in touch with us. At AAC, we pride ourselves on our ability to create customized test setups from scratch to address your distinct needs.