CONSULTING

TESTING

DEVELOPMENT

RESEARCH

Testing

Space environment simulation for material tests

AAC offers a wide range of testing of materials (bulk, films, soils, coatings, paints) for their applicability to space. Orders may start with few single tests, or may range up to large test campaigns. For the latter AAC may also act as one-stop shop.

AAC also offers testing of components. Certain heritage is available for components related to mechanisms, structures and thermal control.

Thermal vacuum (TV) testing is offered for all levels from breadboards (BB) up to flight models (FM) in clean room conditions. Thermal vacuum chambers (TVAC) up to medium size (2m³) are available.

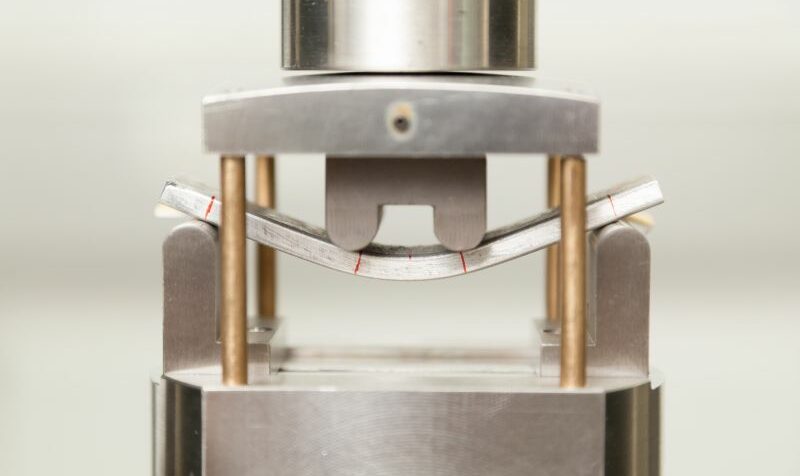

Mechanical testing covers almost all technically relevant temperatures starting from cryogenic level (4K) up to almost re-entry conditions (2200°C).

In addition, post-test analysis is offered. Starting from standard visual inspection, metallographic preparation followed by microscopy from optical up to Scanning Electron Microscopes. The latter offers elemental analysis (EDX), but also crystallographic analysis (EBSD). FIB (focused Ion Beam) enables localised in-situ cross sectioning.

Tribo-Material & Component Testing – Space Tribology: Test Rigs

| Test rig | Samples / Components | Output | Environment |

|---|---|---|---|

| Vacuum Tribometer | Pin/Ball-Disc Slip-Rings | friction, linear wear, el. contact resistance | vacuum, air, CO2 -100 … +300°C |

| Cold Welding Tribometer | Pin-Disc | friction, adhesion | vacuum, air, CO2 |

| Cold weld – Vacuum shaker | 3-Pin-on-Disc Cubesats | Adhesion, HDRM-validation | vacuum, air, CO2 -/+50°C |

| Cryo-Tribometer | 3-Pin-on-Disc | friction, lifetime | vac, gHe, -269°C to RT |

| Journal Bearing Test Rig | Bush-Shaft | torque | vacuum, air, CO2 -100 … +300°C |

| SALOTTE 1 HADES | Gears, brakes, Ball/Plain bearings | torque & lifetime | vacuum, air, CO2 -170 … +250°C |

| SALOTTE 2 ECM | Pin-Disc/Brush/Wire | friction, el. contact-resistance | vacuum, air, CO2 -100 … +300°C |

| Ball bearing test rig BBT | Ball bearings Ring-Ring 3Pin/on-Ring | torque, lifetime, friction | vacuum, air, CO2 RT … +200°C (Vac … +700°C) |

| Ball bearing test rig BBT² | Ball bearings (swiveling) | torque, lifetime, friction | vacuum, air, CO2 -80 … +80°C |