Operating in the challenging environment of space, satellites contend with extreme temperature fluctuations, radiation exposure, and the vacuum of the cosmos. Essential for fortifying these satellites against such harsh conditions and ensuring their longevity, Multi-Layer Insulation (MLI) emerges as a key protective measure. This thermal insulation method, comprised of reflective foil layers separated by low-conductance spacer materials, plays a pivotal role in regulating temperature and maintaining the resilience of satellites in the unpredictable realm of space.

Challenges Posed by Volatile Compounds

While effective in managing thermal conditions, MLI may contain volatile compounds from the manufacturing process. These compounds, if not addressed, have the potential to outgas in the vacuum of space, depositing onto sensitive surfaces and impacting the satellite’s critical systems.

The Role of Thermal Vacuum Bakeouts

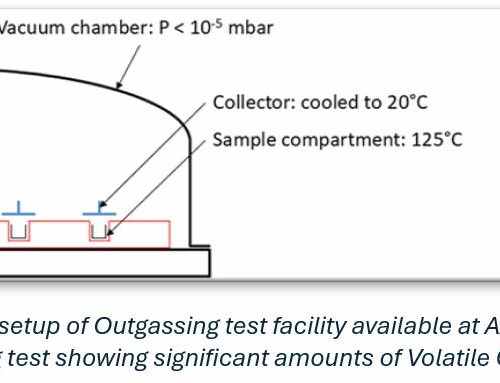

For removing the unwanted volatile compounds, the Thermal Vacuum Bakeout process comes into play. By subjecting the MLI blankets to controlled heating and vacuum conditions, this procedure facilitates the outgassing of volatile compounds from MLI layers. The objective is to purge the insulation of any substances that could compromise the spacecraft’s performance.

The success of the Bakeout is monitored by reference samples (MOC Samples) and TQCM.

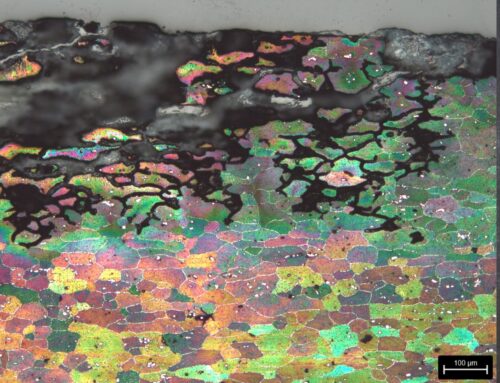

Molecular Organic Contamination (MOC) samples are installed to assess the presence of residual organic compounds at a molecular level after bakeout. These samples are analyzed in laboratories to identify and quantify organic contaminants. Monitoring MOC levels is essential to prevent potential issues and ensure the optimal performance of sensitive aerospace equipment.

A Temperature controlled Quartz Crystal Microbalance (TQCM) is a highly sensitive instrument that measures mass changes at a nanogram level by detecting shifts in the resonance frequency of a quartz crystal. From the frequency change over time the success of the thermal vacuum bakeout of our MLI can be monitored.

Our core competence

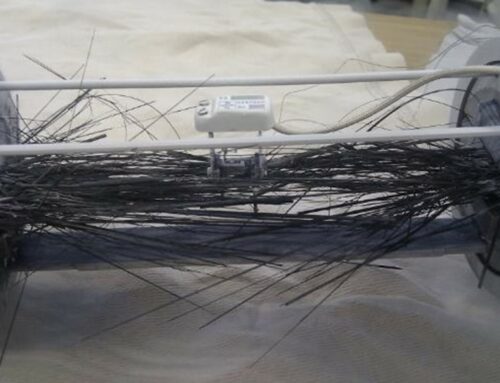

At Aerospace & Advanced Composites (AAC), we operate a specific test rig for multiple MLI blankets in one single bakeout run. The maximum size of the MLI blankets may be 1400x1900mm, larger blankets may be folded. Up to 12 trays of the aforesaid dimensions are available. The facility is located in an ISO 7 cleanroom, allowing the handling of space flight hardware.

Find a detailed description of our facilities here.

Conclusion

The Thermal Vacuum Bakeout of MLI for satellite missions addresses practical challenges, contributing to the resilience and longevity of these essential instruments. By mitigating risks associated with volatile compounds, we enhance overall satellite performance and support ongoing advancements in Earth observation.

Interested in more information? Get in touch with our team of experts at office@aac-research.at or visit us at Aerospace & Advanced Composites: Space Engineering & Technology