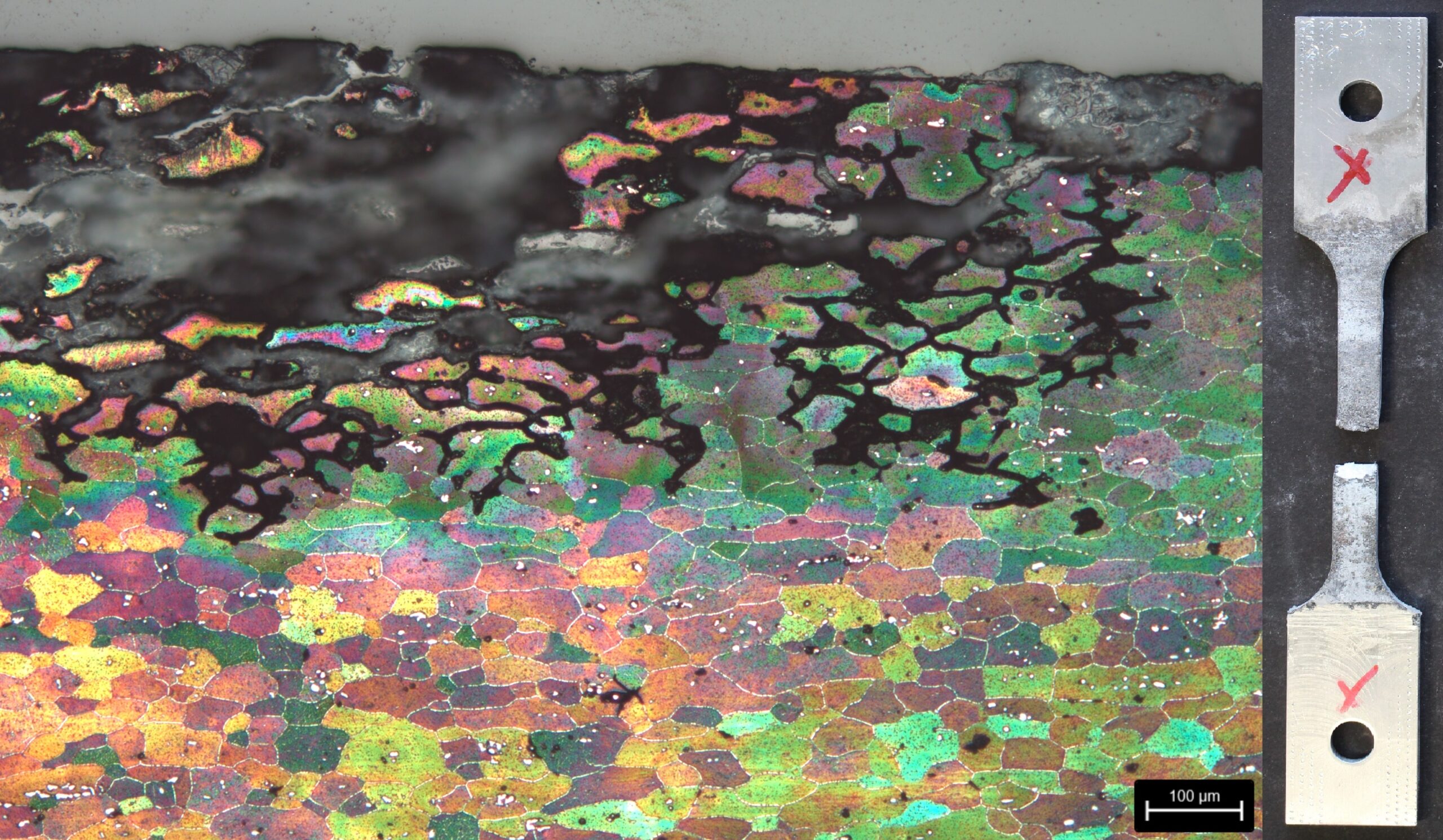

Stress corrosion cracking (SCC) is a critical failure mechanism that occurs due to the combined effect of tensile stress and a corrosive environment on materials. This form of degradation can lead to sudden and catastrophic failures in structures and components, even when the overall corrosion rate is low. SCC is especially dangerous because cracks can grow undetected over time, leading to unexpected structural failure. Therefore, SCC testing is essential for evaluating the resistance of materials in service environments, ensuring long-term integrity and safety in industries such as aerospace, nuclear, chemical processing, and oil & gas.

The susceptibility of metals and its alloys to stress corrosion cracking has been investigated over several decades. Considering the importance of this subject for the safety and reliability of components and equipment in various fields of engineering such as construction, mining, chemical processing and transportation, a series of standards has been established to assess materials susceptibility to SCC. In the multitude of standards (ECSS, ASTM and DIN), the focus of attention is directed towards frequently employed engineering alloys (steel, copper, titanium and aluminium) as well as the conditions in the final applications. From a practical point of view the test procedures described in most of the standards serve as a guideline to “classify” the material in terms of susceptibility to SCC, e.g. low, moderate or high potential of SCC.

SCC conditions

Three conditions must be fulfilled for SCC to appear:

- The materials or components surface subjected to tensile load either by an external source or by residual stress arising from processing (heat treatment, extrusion, forging, welding and mechanical machining).

- The material is exposed to a corrosive medium of acidic or alkaline agent, to hydrogen gas or to solutions with dissociated ions, particularly chloride as in salt water.

- The alloy is inclined to stress corrosion cracking; a combination of material properties and manufacturing factors (e.g. chemical composition, thermomechanical processing history and ageing duration) determine the susceptibility to SCC.

Conclusion

Given the extreme environmental and operational demands in aerospace applications, SCC testing is essential for maintaining structural integrity and preventing failures that could compromise mission success.

AAC’s proven knowledge, extensive experience and broadband material characterizing capabilities help you to predict and prevent potential material failures, guide alloy selection, and determine appropriate protective measures (e.g., coatings, cathodic protection, or stress relief treatments).

Interested in more information? Get in touch with our team of experts at office@aac-research.at or visit us at Aerospace & Advanced Composites: Space Engineering & Technology