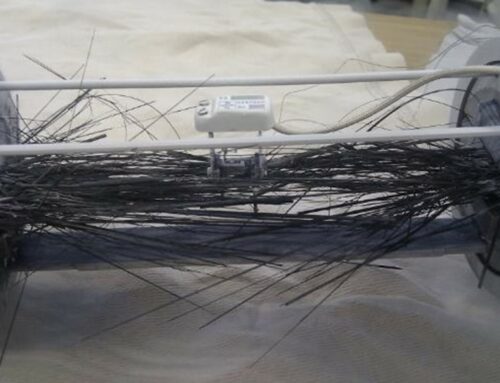

In the realm of industrial challenges, few sectors face the persistent hurdles encountered by the paper industry. From the persistent buildup of residues to the frequent machinery shutdowns for maintenance, the environmental and economic toll is significant. However, among these challenges arises a sign of innovation – the ReleaseNite coatings.

A Breakthrough Collaboration: The Birth of ReleaseNite-Series

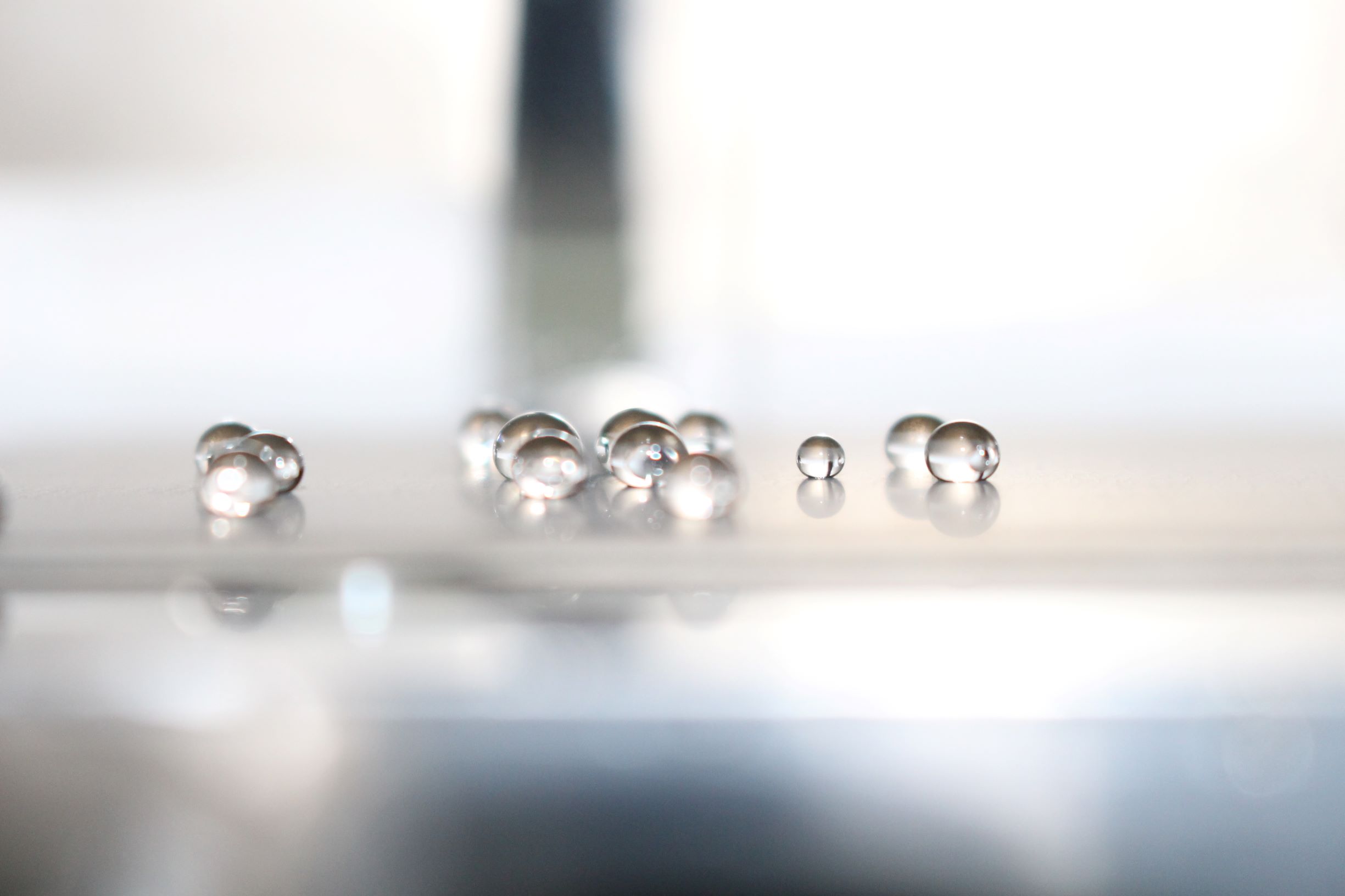

Developed as part of the Austrian COMET program (InTribology project), in collaboration with industry leader FWT Composites and Rolls GmbH and AC2T Research GmbH, Aerospace & Advanced Composites GmbH (AAC) has engineered a game-changing solution for the paper machine sector. The ReleaseNite-Series presents a novel, highly crosslinked, glass-like coating system that redefines durability, ease-of-cleaning, and resistance to corrosive elements.

Addressing Industry Pain Points:

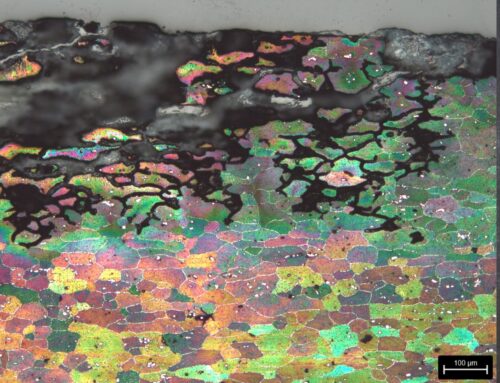

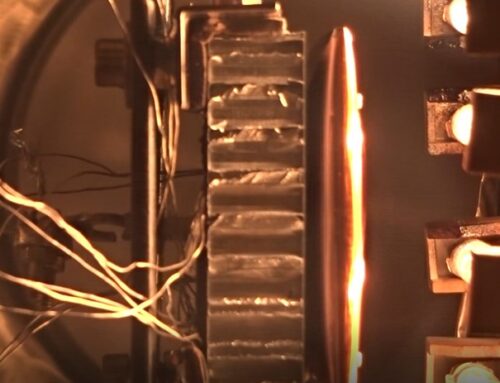

In the paper industry, downtime is not just a financial problem but also an environmental concern. Frequent shutdowns necessitate increased water, chemical, and energy usage, increasing the industry’s ecological footprint. The ReleaseNite-Series tackles this head-on by minimizing residue buildup, thus reducing downtime, maintenance costs, and environmental impact. Its exceptional resistance to wear, water vapors and oxygen, ensures long-lasting performance even in the harshest conditions.

Environmental Consciousness:

One of the characteristic features of ReleaseNite coatings is their PFA-free formulation. Unlike traditional non-stick fluoro-based coatings, ReleaseNite products eliminate the environmental and health risks associated with PFAs, aligning with current EU discussions on environmental sustainability. This not only ensures cleaner water and safer working environments but also underscores our commitment to responsible consumption and production.

Advantages Beyond Performance:

The benefits of ReleaseNite coatings extend beyond their superior performance. With a significantly lower curing temperature (<180°C) compared to the state-of-the-art coatings (fluoro-based >300°C), ReleaseNite-Series offers energy savings and versatility in application. Moreover, its suitability for any component geometry streamlines the coating process, making it accessible to a wide range of industrial needs.

Contributing to Global Goals:

By championing sustainability and innovation, ReleaseNite coatings actively contribute to the achievement of several UN Sustainable Development Goals. From promoting clean water and sanitation (SDG #6) to fostering industry innovation (SDG #9) and responsible consumption and production (SDG #12), ReleaseNite-Series represents a commitment to a brighter, more sustainable future.

Introducing the ReleaseNite Products:

ReleaseNite-TH: a transparent, high-temperature curing system (130 to 180 °C). Its exceptional resilience makes it ideal for environments where extreme conditions and wear are commonplace, ensuring longevity without compromising clarity.

ReleaseNite-B: a room temperature curing system with outstanding antistatic properties and scratch resistance, ideal for special applications.

ReleaseNite-XT: a transparent, room temperature curing system. Designed for ease of application, ReleaseNite-XT provides reliable surface protection without the need for specialized curing conditions, making it an accessible choice for various component needs.

Innovative, environmentally conscious, and high-performing, ReleaseNite coatings indicate a new era in paper machine maintenance. By enhancing durability, extending equipment lifespan, and improving operational efficiency, they pave the way for a more sustainable and prosperous industry landscape. Join us in revolutionizing the paper industry – with ReleaseNite, the future is cleaner, greener, and more resilient than ever before.

Interested in more information or functional coatings? Get in touch with our team of experts at office@aac-research.at or visit us at Aerospace & Advanced Composites: Functional Coatings