CONSULTING

TESTING

DEVELOPMENT

RESEARCH

AAC projects

AAC Research is actively engaged in numerous national and international research and development initiatives, collaborating with esteemed organizations such as the Austrian Research Promotion Agency (FFG), the European Space Agency (ESA), the European Union (EU), and the European Defence Fund (EDF). Through these collaborations, AAC contributes to advancing technologies in aerospace, defense, as well as terrestrial sectors, reinforcing Austria’s and Europe’s strategic autonomy and innovation capacity.

2024

Aerospace & Advanced Composites GmbH is pleased to be part of ENGRT II within a consortium made of 56 partners representing +10 nations all over the European Union.

Airbus Helicopters and Leonardo welcome the selection of the European Next Generation Rotorcraft Technologies Phase II (ENGRT II) project by the European Commission in the frame of the European Defence Fund (EDF). The project, building on European Next Generation Rotorcraft EDF project started in 2022, was proposed by a European consortium composed of leading edge Research Centers, SMEs and Industries gathered by Airbus Helicopters and Leonardo to answer EDF call 2024. Following this selection phase, the European Commission will enter into the grant agreement preparation with the consortium.

2024

LMD4MM – “Laser-Metal-Deposition for Multimaterial Manufacturing”

Duration: June 2024 – May 2026

Funding Source: FFG

Collaborating Partners: RHP-Technology GmbH, AAC

Description: LMD4MM project advances Laser Metal Deposition technology to enable high-precision, multi-material manufacturing for aerospace and industrial applications. By using up to six powder feeders, it enables the in-situ creation of advanced materials like high-entropy alloys, metal matrix composites, and functionally graded materials, opening new possibilities for smart, high-performance components.

2024

ProFilm – “European Protective Thin Films for Space Applications”

Duration: July 2024 – August 2026

Funding Source: ESA

Collaborating Partners: HPS GmbH, AAC, DLR

Description: ESA has funded a €1 million project led by HPS, AAC, and DLR to develop next-generation multifunctional films for space applications. Aimed at improving satellite protection and performance, the project focuses on creating advanced materials with features like ATOX resistance, non-reflectiveness, and adaptability for use in thermal insulation, deorbiting systems, and stealth technologies.

2023

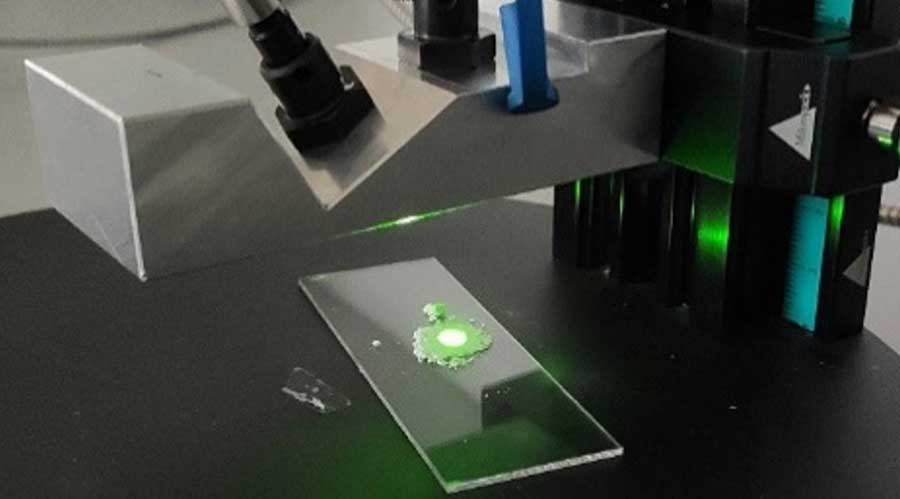

LABELO – “Laser Structured Anti-Icing Coatings for Aerospace Applications”

Duration: October 2023 – September 2025

Funding Source: FFG/BMK

Collaborating Partners: TU Wien, AAC, FH JOANNEUM, INOCON Technologie GmbH, AIIs

Description: Developing durable and highly effective passive anti-icing surfaces for aircraft by combining laser structuring, functional nano-coatings, and a robust plasma coating. Performance is evaluated through experimental icing tests and numerical simulations.

2020

JOICE – “Joint Austrian In-Flight Icing Research Venture 2020+”

Duration: October 2020 – September 2023

Funding Source: FFG/BMK

Collaborating Partners: FH JOANNEUM GmbH, JOANNEUM RESEARCH, LKR Leichtmetallkompetenzzentrum Ranshofen GmbH, Villinger GmbH, Eologix Sensor Technology GmbH, AAC, AeroTex GmbH, ATT advanced thermal technologies GmbH, RTA Rail Tec Arsenal Fahrzeugversuchsanlage GmbH, AIIs, CEST, TU Graz, AIT, KANSAI HELIOS Austria, FACC Operations GmbH, Seoul National University

Description: Project JOICE is Austria’s flagship R&D initiative focused on advancing aircraft icing research. The project develops innovative ice protection systems, enhances simulation tools, and strengthens national expertise in in-flight icing phenomena.

Relevant Links: https://www.project-joice.com/

2020

IMPACT – “Aircraft advanced rear end and empennage optimisation enhanced by anti-ice coatings and devices”

Duration: September 2020 – August 2023

Funding Source: EU

Collaborating Partners: AIT, AAC, CEST, RTA Rail Tec Arsenal Fahrzeugversuchsanlage GmbH, Università degli Studi di Napoli Federico II, SmartUp Engineering S.r.l., University of Southampton, Eurotech Di Mario Amoroso SAS, Università degli Studi di Udine

Description: The IMPACT project, part of the EU’s Clean Sky 2 program, focuses on optimizing aircraft rear fuselage and empennage designs by integrating passive anti-icing technologies. Led by the Austrian Institute of Technology, the consortium of ten partners from Austria, Italy, the UK, and Canada aims to enhance aerodynamic efficiency and safety through advanced 3D ice accretion simulations, innovative aerostructural optimization methods, and large-scale icing wind tunnel validations.

Relevant Links: https://www.impact-cleansky-project.eu/

2020

LiBio – “Lightweight Bionic Aircraft Interior – Entwicklung von Multimaterial-3D-Druck und multifunktionalen Beschichtungen”

Duration: May 2020 – November 2023

Funding Source: FFG

Collaborating Partners: JOANNEUM RESEARCH, KANSAI HELIOS Austria GmbH, F. LIST GMBH, INOCON Technologie GmbH, ANTEMO Anlagen & Teilefertigung GmbH, AAC

Description: LiBio is a transnational R&D initiative revolutionizing aircraft cabin design through sustainable, bionic-inspired components using advanced multi-material 3D printing. By combining innovative surface finishes and lightweight structures, the project enhances aesthetics, functionality, and passenger comfort while meeting strict aviation standards.

Relevant Links: https://projekte.ffg.at/projekt/3337099

2018

LubRes – “Novel anti-ice surfaces based on lubricant reservoirs in polymer coatings”

Duration: January 2018 – June 2021

Funding Source: FFG

Collaborating Partners: CEST, KANSAI HELIOS Austria GmbH, AAC, RTA Rail Tec Arsenal Fahrzeugversuchsanlage GmbH

Description: The LubRes project aims to develop innovative, ice-repellent coatings for aircraft that offer long-lasting protection against ice formation and erosion. By embedding lubricating liquids into functionalized paint matrices the coatings can maintain their anti-icing performance over time, even under wear. This technology enhances flight safety, reduces maintenance needs, and contributes to lower emissions in the aerospace industry.

Relevant Links: https://projekte.ffg.at/projekt/2758292

2014

IceDrip – “Aircraft anti-icing and de-icing through assemblies of conducting varnish and functional coatings”

Duration: April 2014 – September 2016

Funding Source: FFG

Collaborating Partners: FH JOANNEUM GmbH, AAC, JOANNEUM RESEARCH, KANSAI HELIOS Austria GmbH, RTA Rail Tec Arsenal Fahrzeugversuchsanlage GmbH, Villinger GmbH

Description: The IceDrip project explores the integration of advanced electro-thermal ice protection systems with (super)hydrophobic surface coatings to enhance energy efficiency and reliability in aviation. By combining continuous anti-icing at the leading edge with targeted de-icing further downstream, and optimizing ice-shedding through water-repellent surfaces, the project aims to reduce energy consumption while ensuring effective and consistent ice removal.

2011

Rotorblattenteisung – “Produktivitätssteigerung durch Management von Eisansatz an Rotorblättern”

Duration: October 2011 – March 2014

Funding Source: FFG

Collaborating Partners: LKR Leichtmetallkompetenzzentrum Ranshofen GmbH, WEB Windenergie AG, AAC, STERNWIND Errichtungs- und Betriebs- GmbH, AIT, Villinger GmbH

Description: The Rotor Blade De-Icing project aims to reduce wind energy production losses caused by icing, particularly during winter months when other renewable sources like hydropower and solar generate less energy. By minimizing these losses, the project contributes to lowering reliance on fossil fuels and reducing CO₂ emissions. Research focuses on three innovative technological approaches: utilizing sublimation to prevent ice buildup, developing specialized blade surface coatings, and implementing active electrical de-icing systems.

2011

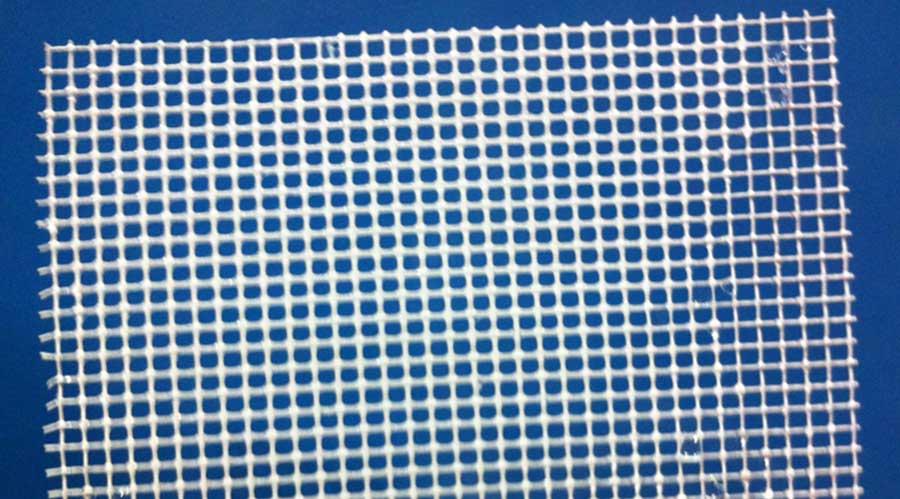

IceGrid – “Untersuchung von Eisbildung auf Rückhaltegittern im Klimatisierungssystem von Luftfahrzeugen”

Funding Source: FFG

Collaborating Partners: FH JOANNEUM GmbH, AAC, Airbus Deutschland, Cavotec GmbH, Icon, TU Graz, Villinger GmbH

Description: The IceGrid project focused on preventing ice formation on protection grids in aircraft air-conditioning systems and ground-based climate modules. By combining heating paints and ice-repellent coatings, and validating performance through icing wind tunnel tests and simulations, the project successfully demonstrated that heated grids could prevent ice buildup while minimizing heat impact on airflow—enhancing reliability and efficiency in aerospace climate systems.

This is how we approach your project

Our team will analyze your situation and recommend a suitable procedure

Your Content Goes Here

Contact us for a non-binding initial consultation.

Your Content Goes Here

We analyze your requirements and create the right offer for you.

Your Content Goes Here

We involve you interactively in the project implementation until it is successfully completed.